|

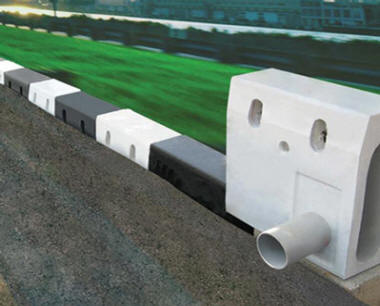

Dual Adonis Polymer Channels:

AP 500 and AP 700 are dual

channels made of

polymer-enriched concrete based

on cement, which are appropriate

to collect and redirect of

surface waters in the streets,

alleys, highways, parking and

all public places in terms of

the required flow rate.

The two-functional channels have

been designed and manufactured

with extensive research and

reviews of all the problems in

the country. Also, these

channels are designed and

manufactured with researches of

the Iranians experienced

engineers who are aware of all

problems in collecting and

redirecting the countryís

surface waters.

There are two holes in these

channels which are placed on the

asphalt surface and rain water

easily enters into the channels.

These channels allow collection

of moisture underneath the

asphalt in such a manner that a

small tube is installed from the

curb to underneath pavement

which can slowly collect

moisture into the channel after

rain. Prolonging the asphalt

life is one of the most

important issues in the economic

debate of the system.

Calculation of Flow rate of AP

500:

Calculation of Flow rate of AP

700:

Merge of Smart Parts of Adonis

Polymer :

Two-function channels of Adonis

Polymer are parts which serve

two functions upon one

installment:

1. They act like an isolator

similar to other ordinary curbs

2. Like drainage channels, they

collect and direct surface

waters

Such channels have the

capability, if needed, to be

joined and connected to other

parts manufactured by this

company. Two examples are

explained herein below:

1. Imagine two-function channels

are installed in a street in

which there are some entrances

like car parks. These channels

are installed across the street

up to the corner of each

entrance, and intelligent

reticulated channels are used at

the entrance of the car parks

and for the rest, two-function

channels are installed. One of

the features of such a merge is

that there will be no need to

ponceau; moreover, there will be

no problem for water flow in

entrance of car parks. It must

be noted that this company has

attempted to manufacture all

parts related to collection and

direction of surface waters in a

way that in no point of the

project line, there is obstacle

to water flow; otherwise, all

attempts in designing and

manufacturing these parts would

be in vain.

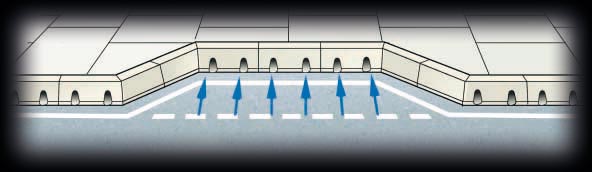

2. The second example is related

to connection of two-function

channels to first class

municipal channels which is

carries out using plastic pipes.

This connection might be either

horizontal or vertical. In

addition, the project line of

executing two-function channels

using plastic pipes may have an

entrance or exit.

|

|

|

|

Advantages of Using Adonis

Polymer Two-Function Channels :

1. Concrete strength of

two-function channel is

approximately 80 megapixel which

is 3 times as much as that of

ordinary curbs, i.e. 30

megapixel, and this increases

the durability of such channels

(special weight of this concrete

is 2670).

2. Because of using silica in

concrete used in two-function

channels, they have high

resistance to acid and corrosive

substances; however, this is not

true for ordinary curbs.

3. Due to using inorganic

substances in these channels,

the degree of channelsí

penetrability to water is almost

zero, and this feature is so

high in ordinary curbs.

4. Because of using some certain

polymers in manufacturing these

two-function channels, they have

a level and shiny surface, and

this increases their capability

of being colored and durability

of the color to a large extent.

5. As the figure as to the

section of two-function channel

shows, this channel has water

flow capability with fall rate

of 50 mm/h, discharge rate of

25.7 lit/s from drainage basin

1497 Sq. m.; however, ordinary

curbs have maximum water flow

capability with fall rate of 5

mm/h, discharge of 0.86 lit/s

from drainage basin 730 Sq. m.

To compare these two,

performance of two-function

channel is much better and more

effective (longitudinal slope is

considered 0.5).

6. In designing this channel,

since drainage operations are

performed lower than asphalt

level, the asphalt itself is not

damaged; however, in ordinary

curbs, asphalts are vulnerable

during their useful life.

7. Because the drainage

operation is fulfilled in the

closed section, there is not the

possibility of obstruction by

leaves and debris which is very

important in terms of

environment and beauty.

8. According to the interior

section of dual channel, mice

and vermin cannot live and grow

there because of the curved

surface.

9. Due to the use of polymer

materials in the construction of

this channel and having a very

smooth surface, the growth of

moss and algae and sludge in the

section of this curb is not

possible.

10. At the time of execution,

because drainage operations and

directing surface water are

performed simultaneously, the

speed of execution is twice than

the execution of Kanio curb and

small streams which are executed

in two-part basis.

11. With regard to the channel

width, at the time of execution,

there are fewer earthworks for

placing the curbs which is

noteworthy in the cost of

execution.

12. These channels have the

capacity of simultaneous

drainage of pavement and

sidewalks.

13. These channels allow the

installation of drainage pipes

for water penetrated to

underneath the asphalt.

14. Due to the small entrance

holes and closed system, there

is no possibility of entering

large junks that this feature

prevents closing the passages

that is important

environmentally.

15. The channels are

manufactured in different colors

using colorfast polymeric

pigments.

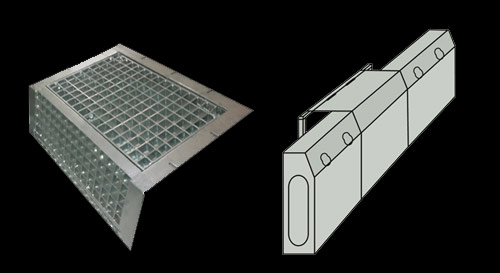

16. To prevent sediment and the

entry of probably tiny debris

(smaller than the size of the

entrance hole) and also for

filtering the channel, every 15

m in length a gully box valve of

stainless steel plate (ribbed 6

Mill) with the same shape of the

channel and dimensions of the

curb is executed with channel

table with garbage-stuck filter.

17. Easy installation and high

speed at the time of

installation in respect of fixed

channels which leads to less

traffic volume at the time of

project performance.

18. Widening of streets and

making the traffic flow

19. Applicable in all of Streets

arches such as squares and etc.

by changing the channels to

Farsi basis

20.

Suitable for sites with

extremely low gradient. It is

noteworthy that the gradient

problems will be strictly

removed with the techniques of

Adonis Polymer experts and using

the parts of this company.

21.

Suitable for areas where metal

manhole has been used for

collecting and redirecting

surface water which has created

many difficulties for vehicles,

motor cyclists, and etc. by

using dual channels, no manholes

is required.

22. Ideal for locations that

have the rumble strip or the

traffic stations.

23. Suitable for city sensitive

places such as bus and taxi

stations that are badly in need

of drainage operations

Dual channel installation

method:

1. Mapping: The mapping should

be prepared from the

installation place of dual

channels and longitudinal

profile so that according to the

code of asphalt and longitudinal

slope, drilling is done.

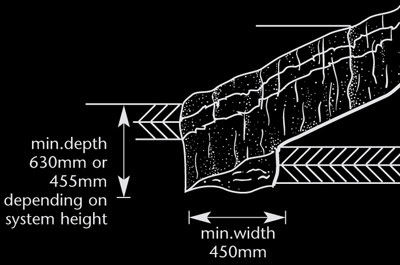

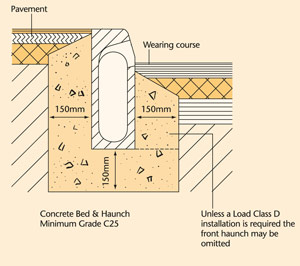

2. Drilling: according to the

height, the drilling is

performed using dual channel.

With regard to the fact that

dual channel bottom should be

used to a height of 15 cm

concrete, dual channel height

should be added to the number 15

and the drilling is done up to

that extent. For example, if the

AP 500 dual channel is used

according to the height of the

AP 500 which is 50 cm, drilling

should be done up to 65 cm (65 =

15 + 50). Drilling width is

equal to the dual channel width

plus 30, dual-channel, because

on each side of the dual

channel, the muscle concrete

with the width of 15 cm should

be implemented.

3. Implementation of floor Mogr

concrete: floor Mogr concrete is

implemented to a height of 15 cm

after digging.

4. Putting dual channel: dual

channel can be installed easily

together after implementation of

Mogr concrete.

5. Implementation of muscle

concrete on both sides and end

of operation: After installing

dual channels together, muscle

concrete is easily implemented

on both sides of dual channel

with the width of 15 cm on each

side and the operation ends.

|

|

Method of asphalt coating after

installing dual channels:

Usually in our country, because

of poor-quality asphalt,

municipalities and

administrative organs had to

repair the road asphalt after 1

or 2 years, and coat the road.

In some cases, it is seen that

in some cities due to lack of

facilities or due to

carelessness of officials, new

asphalt overlays on old asphalt

without cutting the old asphalt,

therefore, the height of the

intended road is greater than

before.

Now the question arises in the

mind that If the dual-channel is

implemented and after passing a

time some officials want to use

the new asphalt on the old one,

the dual channel holes are

closed with elevation of the

road asphalt height? In

response, we should state that

the experienced engineers within

the company have pondered a

solution to this problem; it is

enough that the executor of

asphalt implements the new

coating up to 10 cm to dual

channel, in which case the holes

will have no problem. See the

photo below.

|